Cold chain is very important for dairy products, using USB Temperature Data Logger can monitor the cold chain temperature of dairy products to ensure their quality and safety. As a nutritious food, dairy products are increasingly favored by people.

The cold chain of dairy products refers to maintaining constant temperature control during the entire process of transportation, storage, distribution, and sales of dairy products from production to consumers to ensure the quality and safety of dairy products. Different dairy products have different cold-chain temperature requirements. For example, milk should be stored and transported within a temperature range of 0-4°C; yogurt should be stored and transported within a temperature range of 1-4°C; different types of cheese have different cold-chain temperatures Requirements, but generally speaking, it should be stored and transported within the temperature range of 2~8°C. Butter should be stored and transported at a temperature range of 2~10°C; ice cream should be stored and transported at a temperature below -18°C. No matter what kind of dairy products, they need to be stored and transported in strict accordance with the corresponding temperature to ensure their quality and safety.

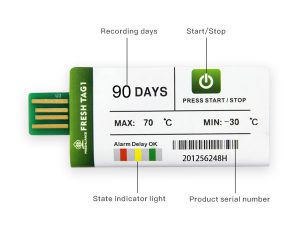

Temperature Data Logger is indispensable for cold chain transportation and storage, especially for dairy products, which have strict temperature requirements and are sensitive. Today I would like to introduce a USB Temperature Data Logger. This product has a built-in USB interface. It does not need a data cable or a card reader. It can be directly connected to a PC or an Android mobile phone. It can directly generate a temperature data report during the trip and transport dairy products after the trip. Or store at ambient temperature for analysis. At present, the USB Temperature Data Logger models launched by Freshliance are relatively complete and can provide different models such as 7 days, 15 days, 30 days, 60 days, 90 days, 120 days, and even 180 days, which can meet the needs of different itineraries.

The cold chain of dairy products is very important to ensure the quality and safety of dairy products. Good temperature monitoring can prevent items from deteriorating. Freshliance can design a reasonable, complete, and cost-effective temperature monitoring solution for the dairy cold chain to ensure the quality and safety of dairy products!

Email: [email protected]

Phone: +86 15517160690

Whatsapp: +8615517160690

Bldg 7, Hengfengkechuang Center, Airport Economic Zone, Zhengzhou, China